Industry knowledge

Precautions for using SPC Flooring Film

When using SPC (Stone Plastic Composite) flooring film, there are a few precautions you should keep in mind to ensure proper installation and maintenance. Here are some general precautions:

Proper handling: Handle

SPC flooring film with care to avoid any damage to the material. Avoid dropping or dragging the film during transportation or installation, as it may result in scratches or tears.

Acclimation: Before installation, allow the SPC flooring film to acclimate to the environment where it will be installed. This helps the material adjust to the temperature and humidity of the space, minimizing the risk of expansion or contraction after installation.

Subfloor preparation: Ensure that the subfloor is clean, smooth, and level before laying the SPC flooring film. Remove any debris, dust, or protrusions from the subfloor to create a suitable surface for installation. Uneven or irregular subfloors can affect the final appearance and performance of the flooring.

Moisture control: SPC flooring film is relatively resistant to moisture, but excessive moisture can still cause damage. Take precautions to control moisture levels in the installation area. Use appropriate moisture barriers or underlayment as recommended by the manufacturer to prevent moisture from seeping into the flooring.

Expansion gaps: Leave proper expansion gaps around the perimeter of the SPC flooring film during installation. These gaps allow the material to expand and contract with changes in temperature and humidity. Follow the manufacturer's guidelines for the recommended gap size.

Avoid sharp objects: Avoid dragging or sliding sharp objects, furniture with sharp edges, or heavy items across the SPC flooring film. These can potentially scratch or damage the surface. Use felt pads or furniture glides under heavy furniture to minimize the risk of scratches.

Cleaning and maintenance: Follow the manufacturer's instructions for cleaning and maintenance to ensure the longevity and appearance of the SPC flooring film. Avoid using harsh chemicals, abrasive cleaners, or excessive water that can damage the surface. Regularly sweep or vacuum the floor to remove dirt and debris.

Prospects for SPC Flooring Film

SPC (Stone Plastic Composite) flooring is a popular type of rigid vinyl flooring that consists of a stone-plastic composite core layer and a wear layer. The wear layer is typically made from a protective film, which can enhance the durability and performance of the flooring. Here are some prospects for

SPC flooring films:

Enhanced Durability: SPC flooring films play a crucial role in protecting the wear layer of SPC flooring from scratches, stains, and wear. As the demand for durable and long-lasting flooring solutions continues to grow, the prospects for SPC flooring films are promising. Manufacturers are constantly improving the quality and performance of these films to meet the increasing expectations of consumers.

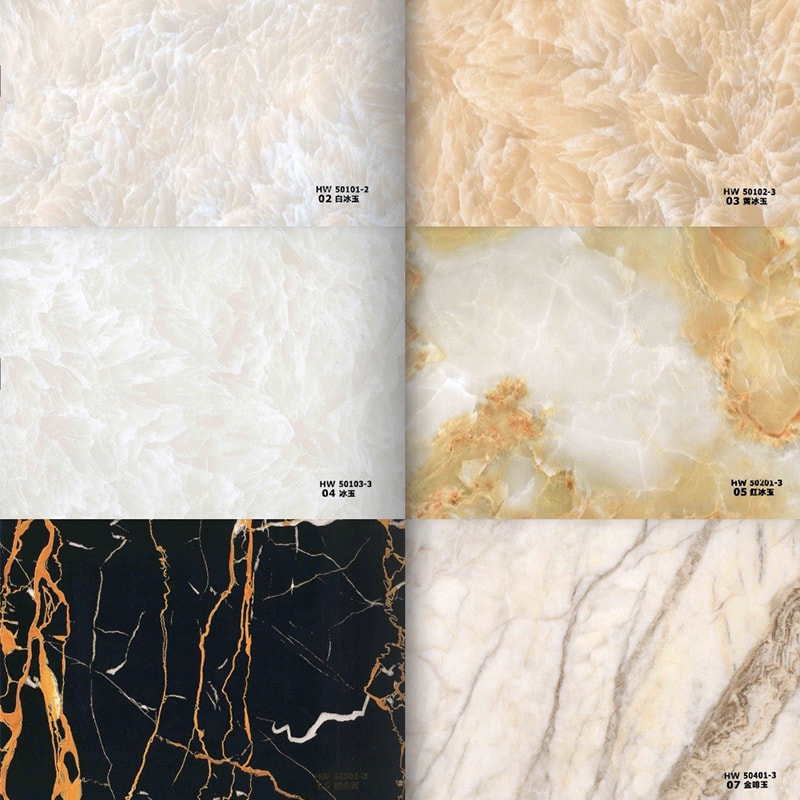

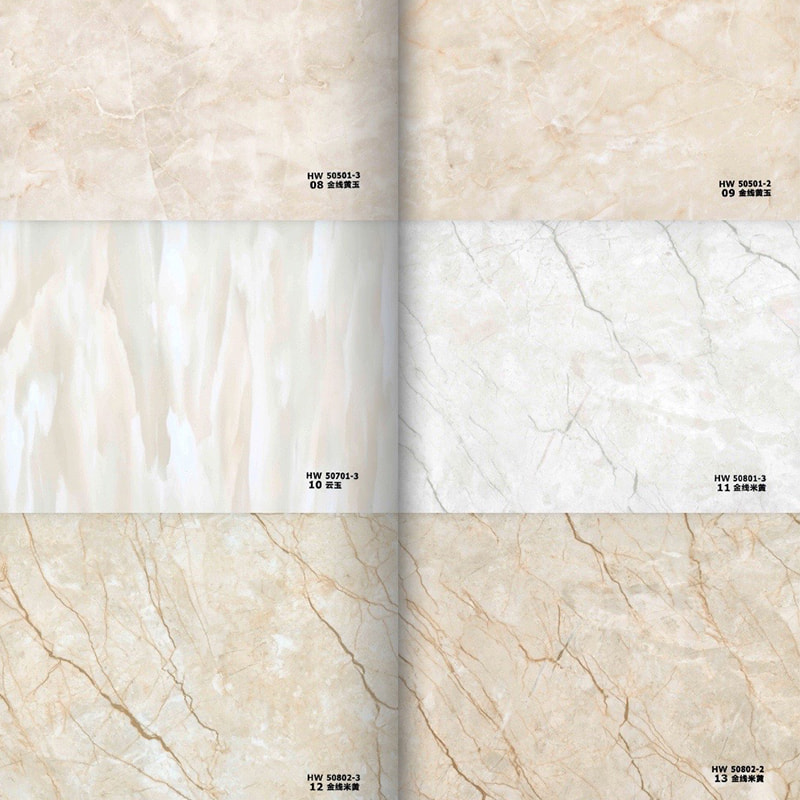

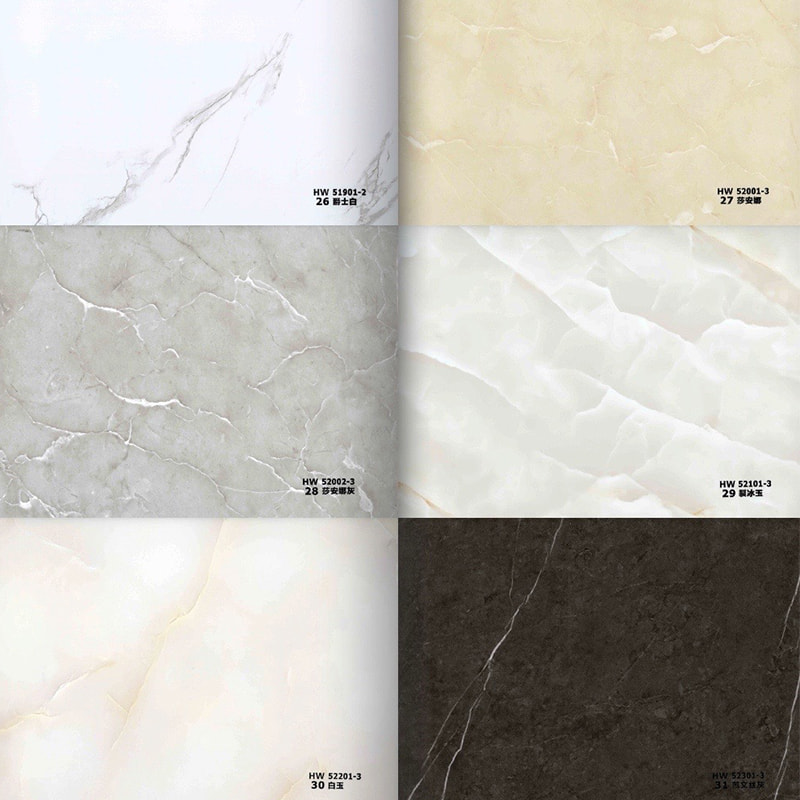

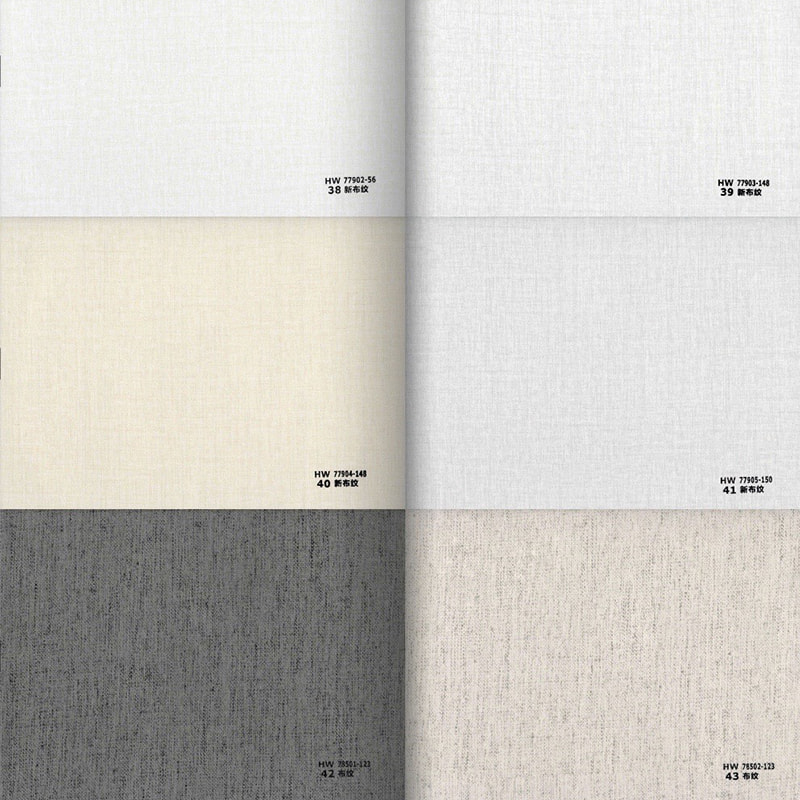

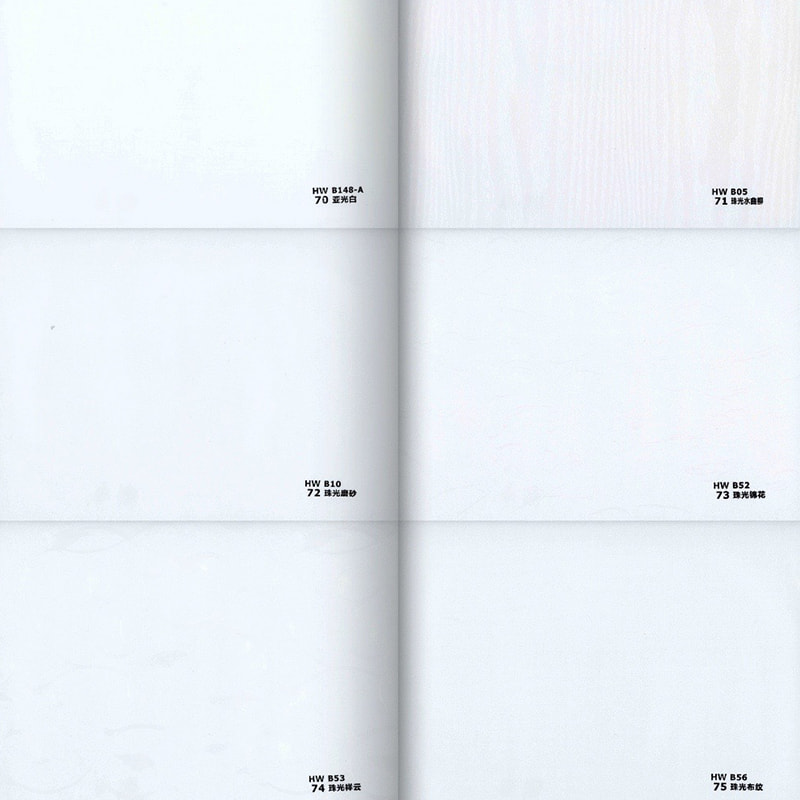

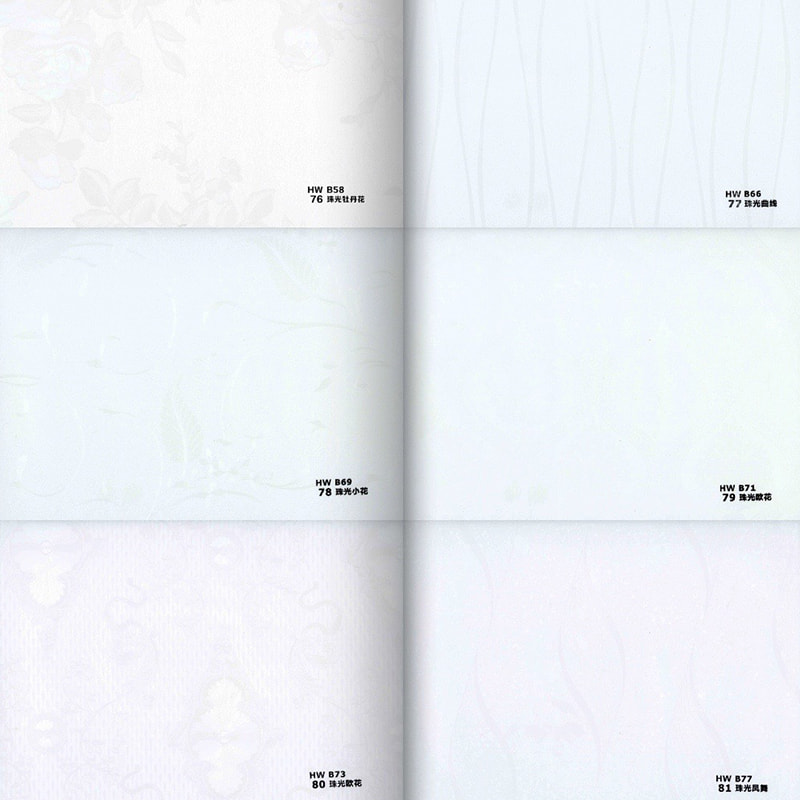

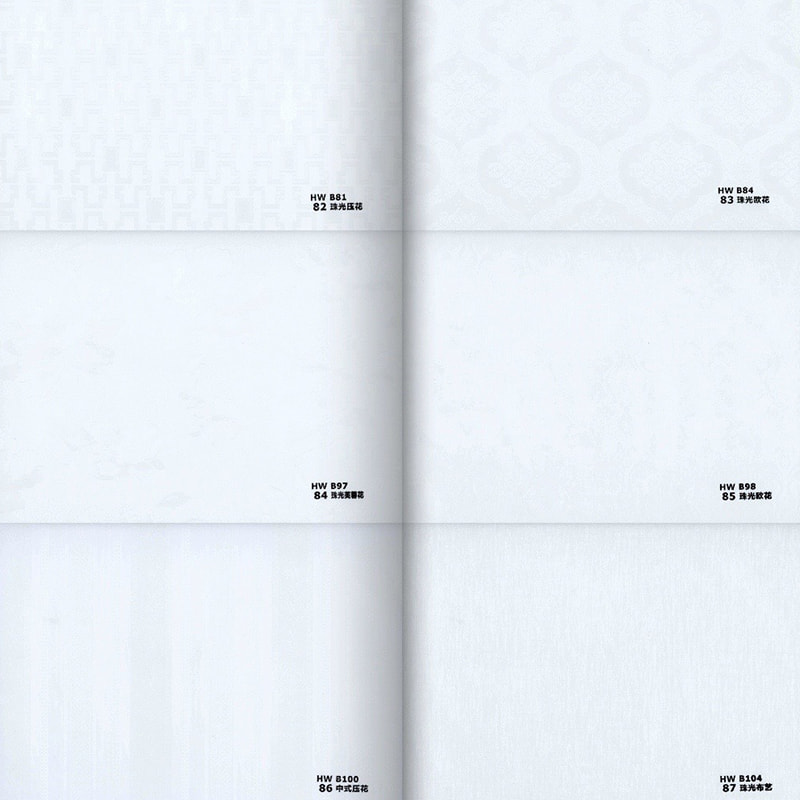

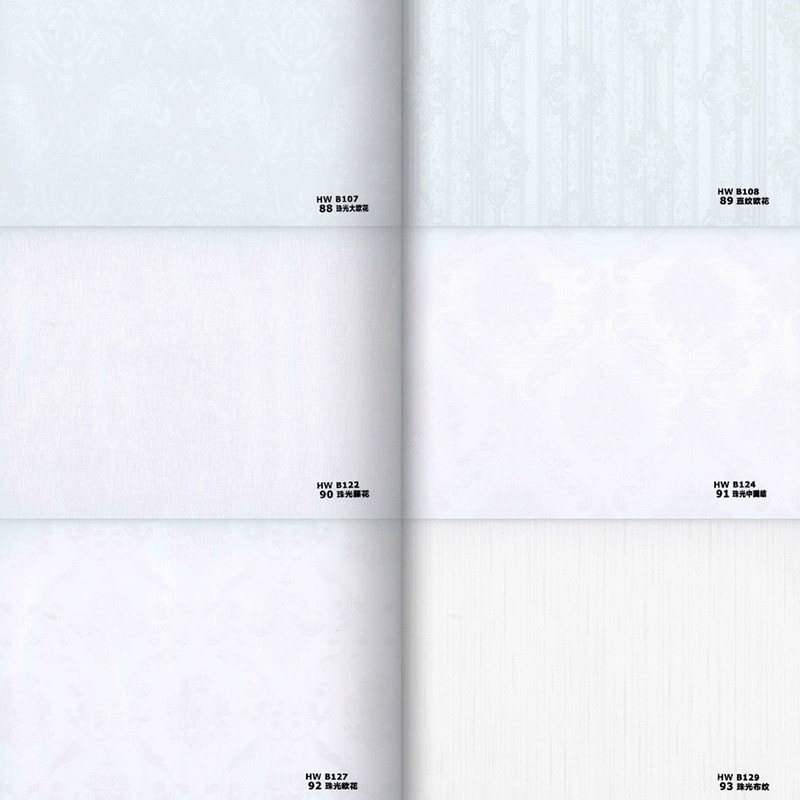

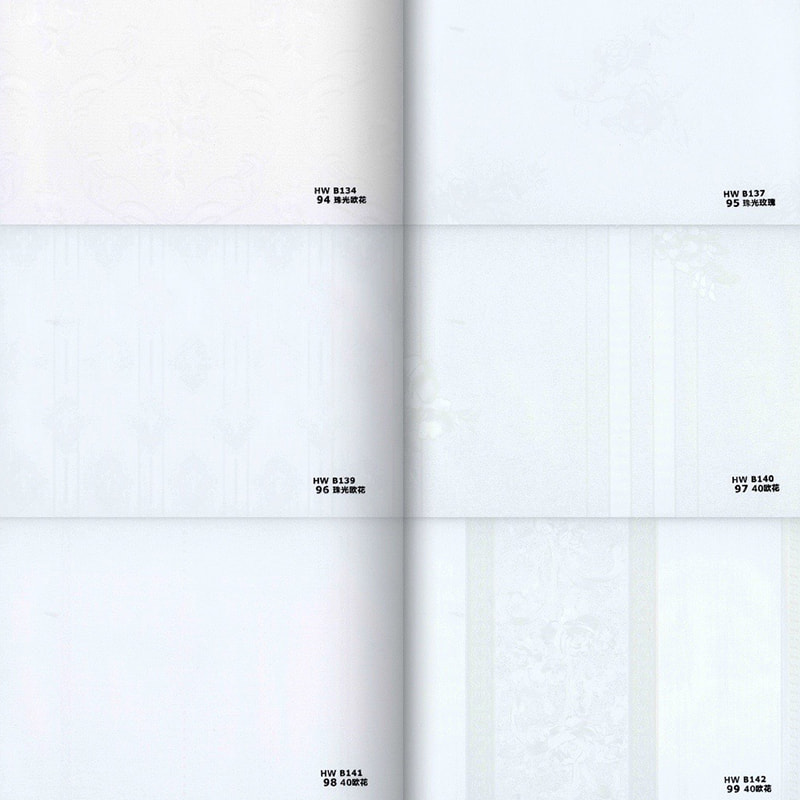

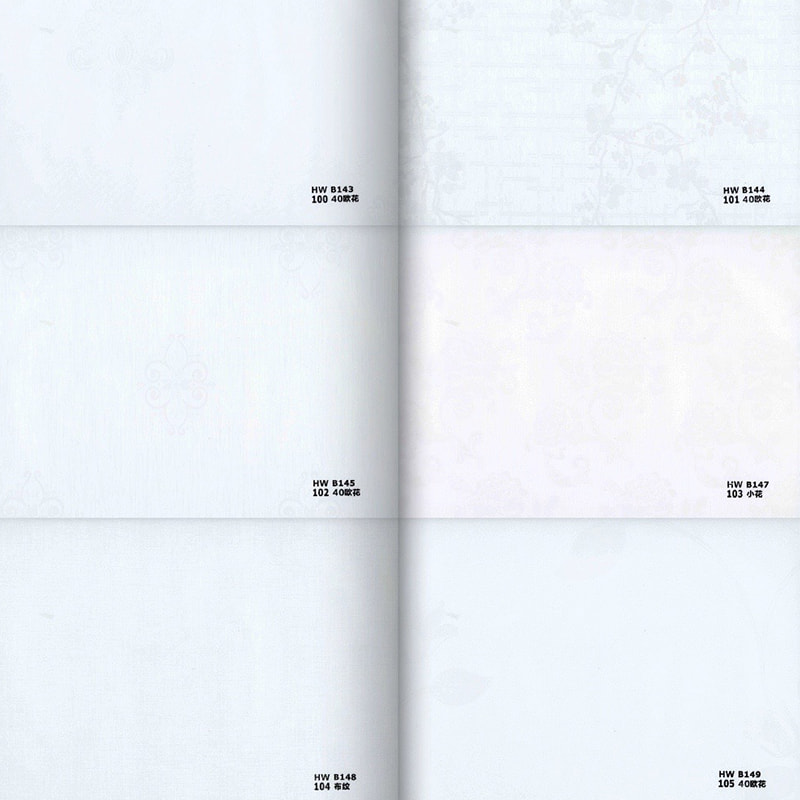

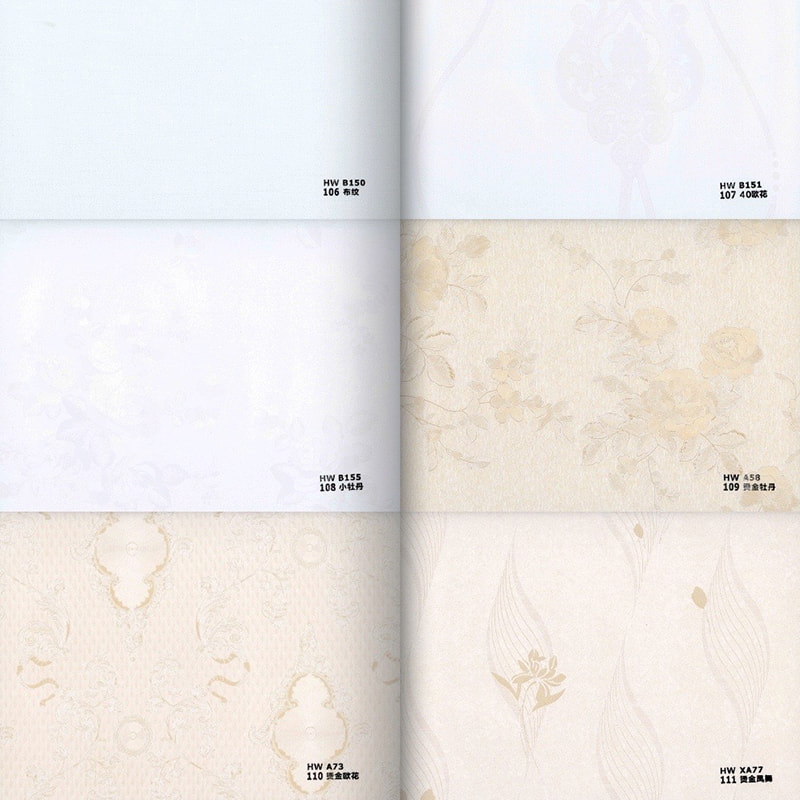

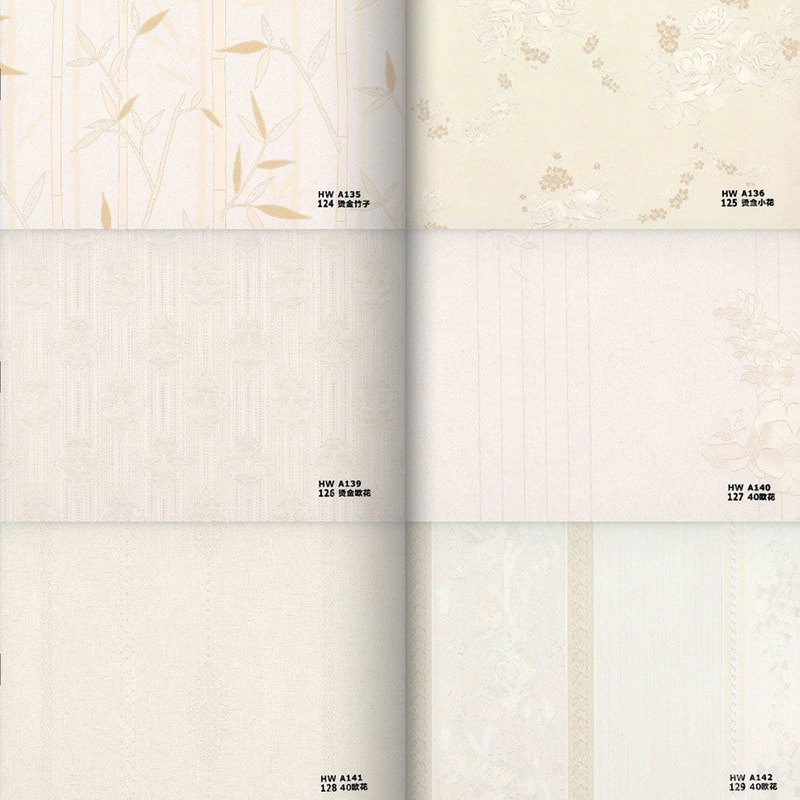

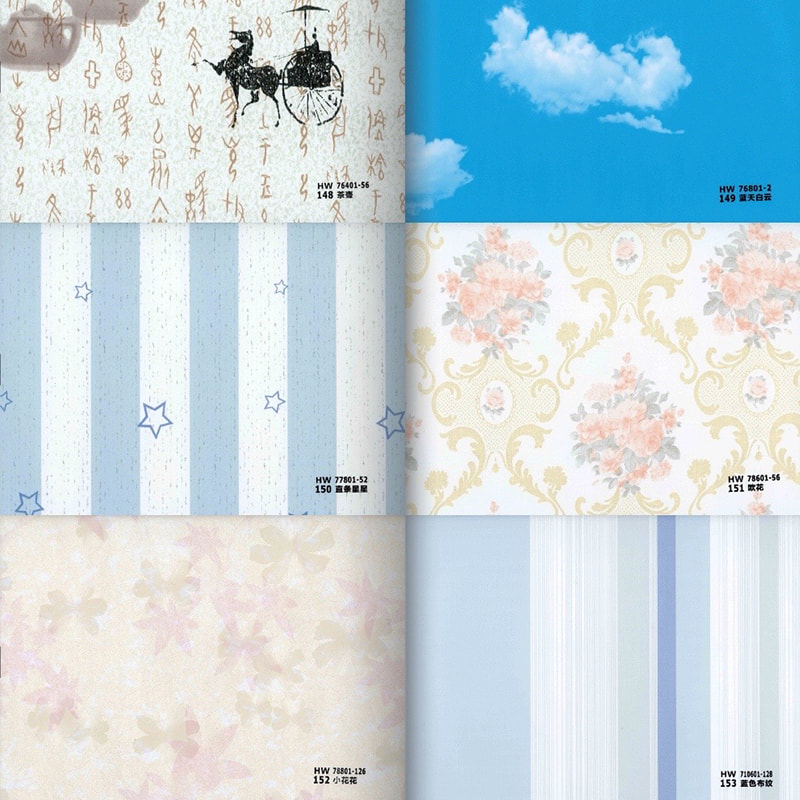

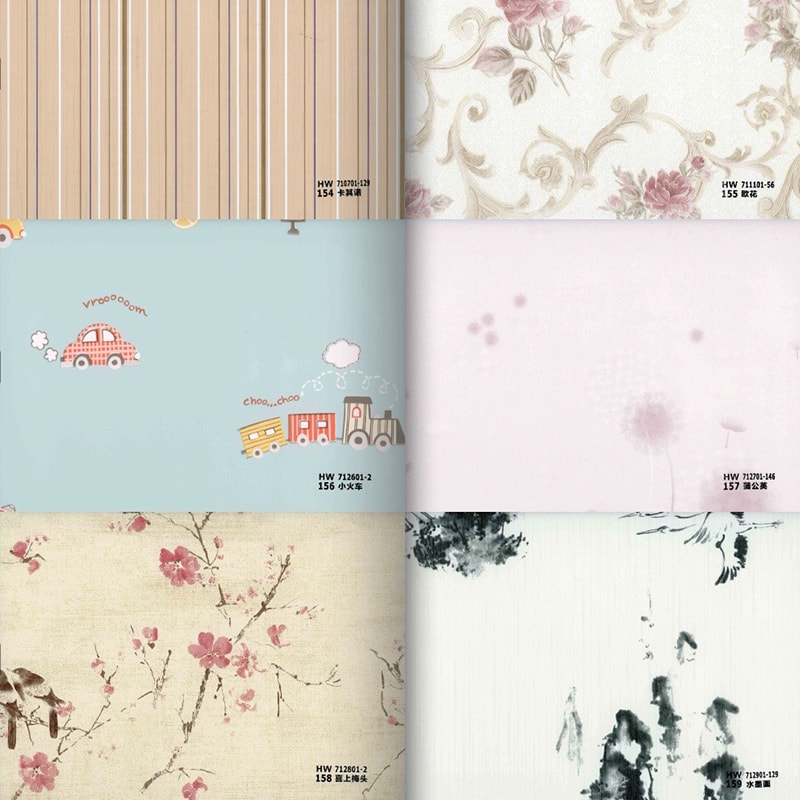

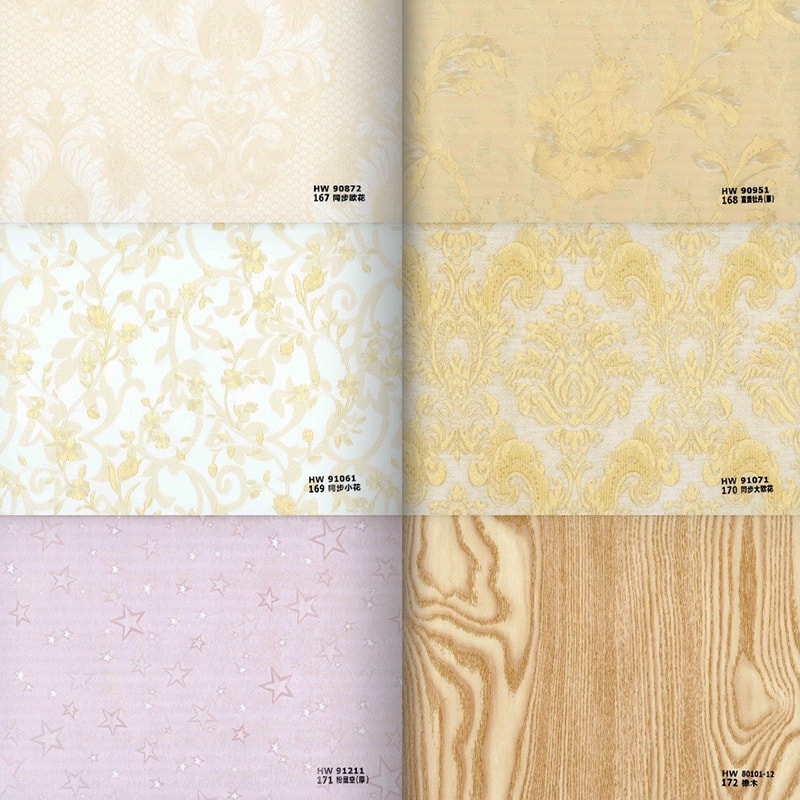

Visual Appeal: SPC flooring films come in a wide range of designs, colors, and patterns, allowing consumers to achieve various aesthetics and mimic the appearance of natural materials like wood or stone. The film layer enhances the visual appeal of SPC flooring and contributes to its overall attractiveness. As the demand for aesthetically pleasing flooring options remains high, the prospects for SPC flooring films that offer diverse and realistic designs are favorable.

Wear Resistance: SPC flooring films are designed to provide excellent wear resistance, protecting the wear layer from daily foot traffic and potential damage. With advancements in film technology, manufacturers are developing wear layers with enhanced performance characteristics such as increased scratch resistance and improved resistance to scuffs and stains. These developments improve the prospects for SPC flooring films, especially in high-traffic areas where durability is a critical factor.

Easy Maintenance: SPC flooring films contribute to the ease of maintenance and cleaning of SPC flooring. The protective film layer makes the flooring surface more resistant to spills, stains, and dirt, allowing for convenient and hassle-free maintenance. As consumers continue to seek low-maintenance flooring options, the prospects for SPC flooring films that facilitate easy cleaning and upkeep are promising.

Environmental Considerations: The prospects for environmentally friendly SPC flooring films are also significant. As sustainability becomes a key consideration for consumers, manufacturers are focusing on developing eco-friendly films with reduced environmental impact. This includes using recyclable materials, minimizing chemical emissions, and adopting production processes that prioritize sustainability. SPC flooring films that align with these environmental concerns are likely to have positive prospects in the market.

English

English

WeChat

WeChat WhatsApp

WhatsApp