Industry knowledge

PET (Polyethylene Terephthalate) base films offer several advantages, making them a popular choice for various applications. Here are some key advantages of PET base films:

Strength and Durability: PET films are known for their exceptional strength and durability. They have high tensile strength, which enables them to withstand heavy loads and resist tearing or puncturing. This makes PET films suitable for demanding applications that require robust protection.

Chemical Resistance: PET films exhibit excellent resistance to chemicals, including solvents, oils, and many common acids and bases. This chemical resistance ensures that the film maintains its integrity and protective properties even when exposed to harsh environments or corrosive substances.

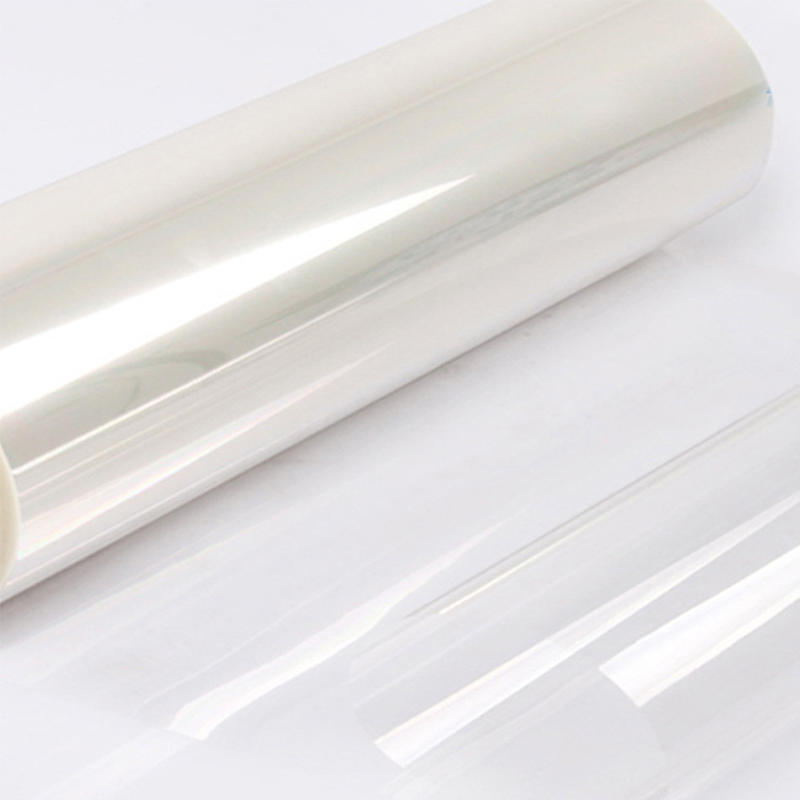

Transparency: PET films have excellent optical clarity, providing high transparency. This feature allows for clear visibility of the protected product or surface, making PET films ideal for applications where visual inspection or display is necessary. They do not significantly distort or obscure the underlying colors or graphics.

Dimensional Stability: PET films have excellent dimensional stability, meaning they resist shrinkage or expansion when exposed to temperature variations. This stability ensures that the film maintains its shape and size, providing consistent protection over time. It also makes PET films suitable for applications requiring precise alignment or registration.

Moisture Resistance: PET films exhibit low water absorption and excellent moisture resistance. They provide a barrier against moisture vapor, preventing moisture-related damage, such as warping, rusting, or degradation of the protected materials. This characteristic makes PET films suitable for applications involving moisture-sensitive products.

Heat Resistance: PET films have good thermal stability and can withstand high temperatures without significant shrinkage or deformation. They have a high melting point, typically above 200°C (392°F), making them suitable for applications that involve heat sealing, laminating, or other thermal processes.

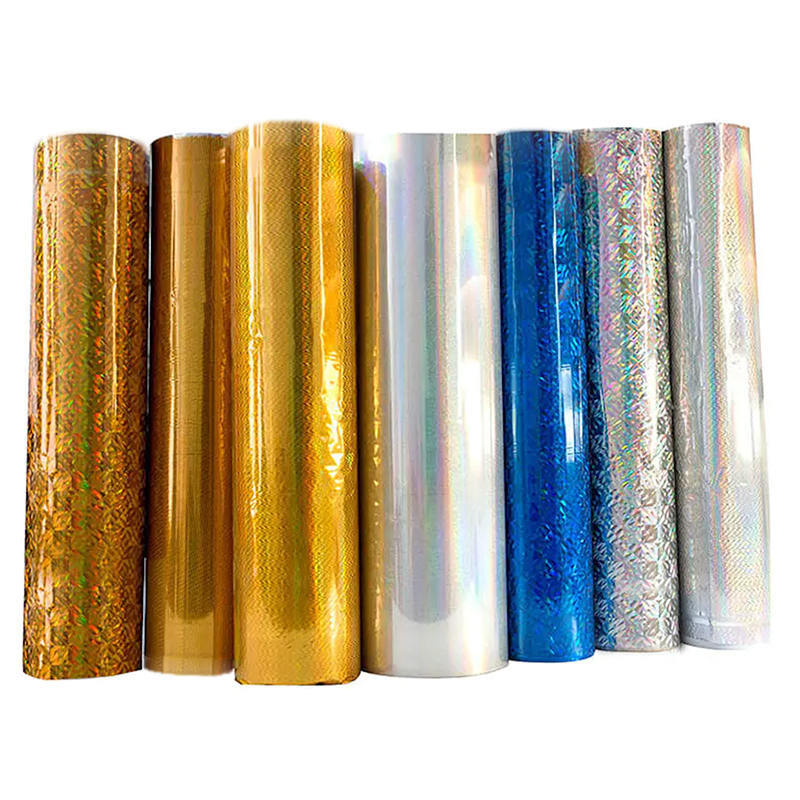

Printability: PET films offer good printability, allowing for high-quality printing and graphics. They can be easily printed using various techniques, such as flexographic printing, offset printing, or digital printing. The smooth surface of PET films ensures accurate reproduction of fine details, vibrant colors, and sharp images.

Environmental Sustainability: PET is a recyclable material, and PET films can be recycled to produce new PET products. They are also lightweight, which reduces transportation costs and energy consumption. PET films can contribute to sustainable practices and support environmental initiatives.

Chemical Composition of PET Base Films

PET (Polyethylene Terephthalate) base films are made primarily from the polymer polyethylene terephthalate. The chemical composition of PET can be broken down as follows:

Polyethylene Terephthalate: The main component of

PET base films is the polymer polyethylene terephthalate itself. It is composed of repeating units of ethylene glycol and terephthalic acid, which undergo a condensation reaction to form the polymer chain.

Ethylene Glycol: Ethylene glycol is a colorless liquid alcohol that is one of the monomers used in the production of PET. It provides hydroxyl (-OH) functional groups that participate in the condensation reaction to form the polymer chain.

Terephthalic Acid: Terephthalic acid is a white crystalline solid that is another monomer used in the production of PET. It contains carboxyl (-COOH) functional groups that react with the hydroxyl groups of ethylene glycol to form ester linkages, resulting in the formation of the polymer chain.

Additives: PET base films may also contain various additives to enhance their performance and properties. These additives can include:

Plasticizers: Plasticizers may be added to improve the flexibility and handling characteristics of the film.

Stabilizers: Stabilizers, such as antioxidants and UV absorbers, can be incorporated to protect the film from degradation caused by heat, light, or exposure to other environmental factors.

Slip Agents: Slip agents are used to reduce the coefficient of friction on the film surface, making it easier to handle and process.

Colorants: Colorants, such as dyes or pigments, can be added to give the PET film a specific color or appearance.

Flame Retardants: In some cases, flame retardants may be incorporated into the film to improve its fire resistance properties.

It's important to note that the exact composition and concentration of additives can vary depending on the specific requirements and intended applications of the PET base film.

English

English

WeChat

WeChat WhatsApp

WhatsApp