Testing the tensile limit or tensile strength of PE Protective Film involves subjecting the film to a controlled force in order to measure its ability to withstand stretching or pulling before breaking. Tensile testing is essential for evaluating the film's mechanical properties and ensuring it meets the required specifications for its intended application. Here are the steps to test the tensile limit of PE Protective Film:

Materials and Equipment:

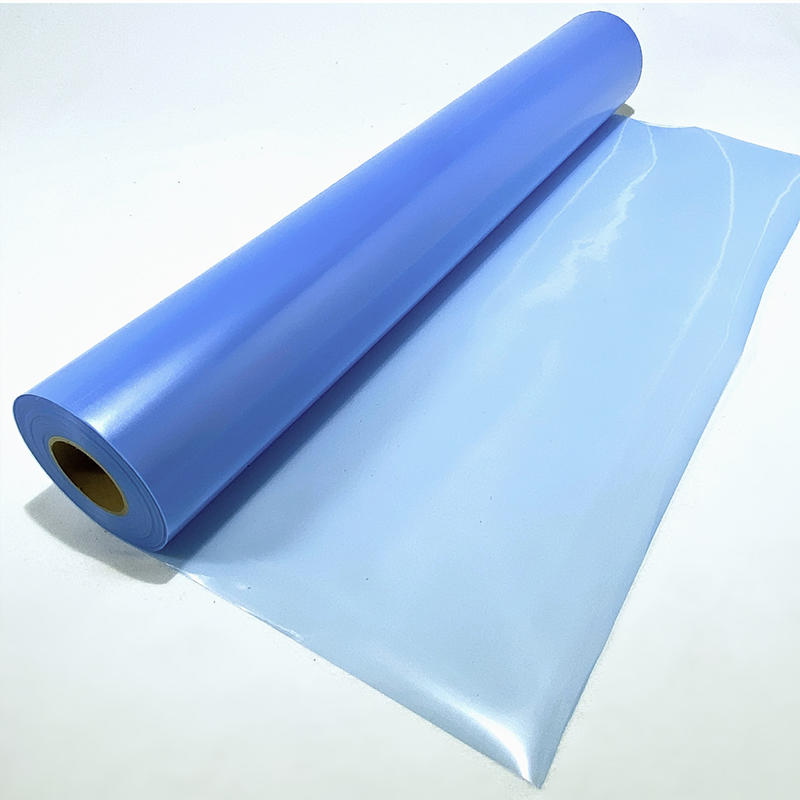

- PE Protective Film sample

- Tensile testing machine (universal testing machine)

- Grips or clamps suitable for film testing

- Computer or data acquisition system

- Calipers or a thickness gauge

- Safety equipment (gloves, safety glasses)

Procedure:

1. Sample Preparation:

- Cut a representative sample of the PE Protective Film to the desired dimensions for testing. The sample should typically be a strip with a specified width and length.

2. Measure Sample Thickness:

- Use calipers or a thickness gauge to measure the thickness of the film. Record this value in millimeters (mm).

3. Machine Setup:

- Set up the tensile testing machine according to the manufacturer's instructions. Ensure that the machine is calibrated and capable of applying a controlled and uniform pulling force.

4. Grip Attachment:

- Attach the grips or clamps to the ends of the film sample securely. Make sure the grips are aligned properly to ensure a uniform distribution of force during testing.

5. Preload:

- Apply a very small initial force (preload) to the film to ensure it is taut and properly aligned within the grips. The preload should be just enough to eliminate any slack in the sample.

6. Testing Parameters:

- Configure the tensile testing machine to perform a uniaxial tensile test. Set the testing parameters, including the pulling speed (crosshead speed) and the desired test limit (e.g., elongation or force limit).

7. Test Execution:

- Initiate the test by activating the tensile testing machine. The machine will apply a steadily increasing force to the film sample, causing it to stretch.

8. Data Collection:

- The machine's data acquisition system will continuously record the applied force and the elongation (stretching) of the film sample as it is being pulled.

9. Monitoring and Analysis:

- Continuously monitor the test and observe the film's behavior. Note any changes in the force-elongation curve, such as yield points, elongation at break, and ultimate tensile strength.

10. Test Termination:

- The test can be terminated either when the film sample reaches its breaking point (rupture) or when it exhibits a specified level of elongation, depending on the test criteria.

11. Data Analysis:

- Analyze the recorded data to determine the tensile strength, elongation at break, and other relevant mechanical properties of the PE Protective Film.

12. Report Results:

- Prepare a test report that includes details of the test setup, the film's dimensions, the testing machine's parameters, and the measured tensile properties. Include any relevant graphs or charts.

Tensile testing provides valuable information about the mechanical performance of PE Protective Film and ensures that it meets the required standards and specifications for its intended use. The results can help manufacturers and users assess the film's durability, strength, and suitability for protecting various surfaces and materials.

English

English

WeChat

WeChat WhatsApp

WhatsApp