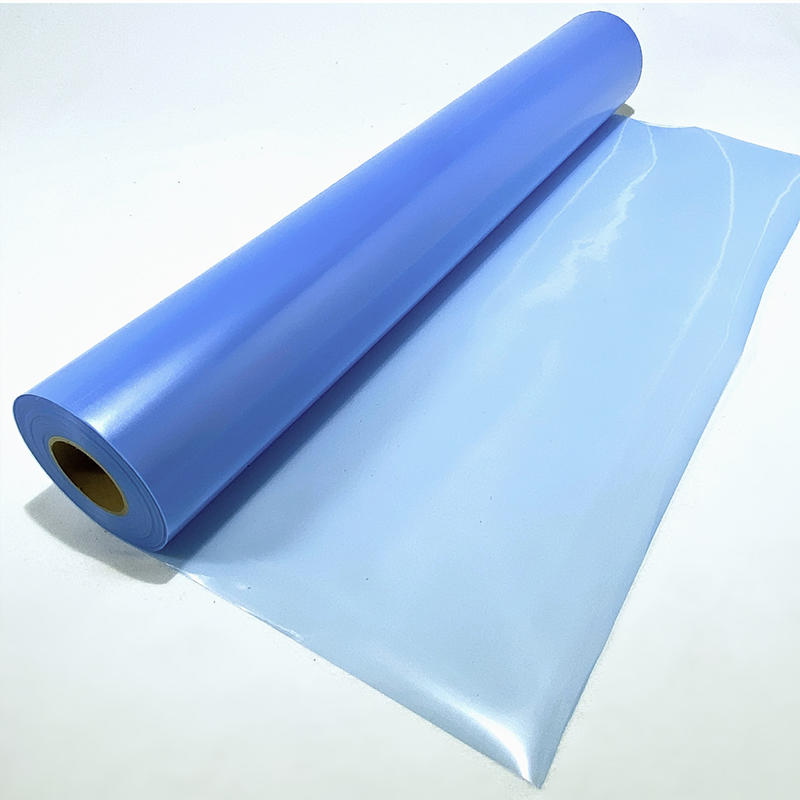

PE Protective Film is designed to adhere to surfaces and provide protection, but its adhesion may weaken if it is stretched or elongated excessively. To ensure that PE Protective Film remains sticky when stretched to some extent, you can consider the following precautions and practices:

1. Select the Right Film Type:

- Start by selecting a PE Protective Film that is specifically designed to withstand stretching and elongation without losing its adhesive properties. Not all protective films are suitable for applications where stretching is required.

2. Understand Stretch Limits:

- Know the stretching limits of the chosen PE Protective Film. Manufacturers typically provide guidelines regarding the film's maximum stretchability. Exceeding these limits may compromise adhesion.

3. Proper Surface Preparation:

- Ensure that the surface to which the film will be applied is clean, dry, and free from contaminants. Proper surface preparation is essential for optimal adhesion, especially when stretching is involved.

4. Apply Even Tension:

- When applying the film to a surface that requires stretching, apply even tension across the film to prevent localized stress points. Uneven tension can lead to adhesive failure in certain areas.

5. Use Application Tools:

- Consider using application tools, such as rollers or squeegees, to evenly distribute the film and apply it with consistent pressure. These tools can help ensure good contact between the film and the surface.

6. Avoid Excessive Stretching:

- Be cautious not to overstretch the film during application. Stretching it beyond its designed limits may cause the adhesive to weaken or lose its effectiveness.

7. Adhere to Manufacturer's Recommendations:

- Follow the manufacturer's instructions and recommendations for the proper application and stretching techniques specific to the chosen PE Protective Film. These guidelines are based on the film's formulation and intended use.

8. Temperature Considerations:

- Pay attention to temperature conditions during stretching and application. Some films may perform differently at extreme temperatures, so it's important to consider environmental factors.

9. Consider Edge Sealing:

- In applications where stretching is expected, it may be beneficial to consider edge sealing or using an additional adhesive along the edges of the film to enhance adhesion and prevent edge lift.

English

English

WeChat

WeChat WhatsApp

WhatsApp