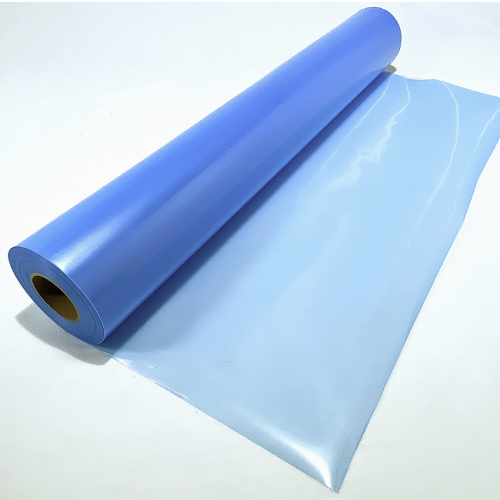

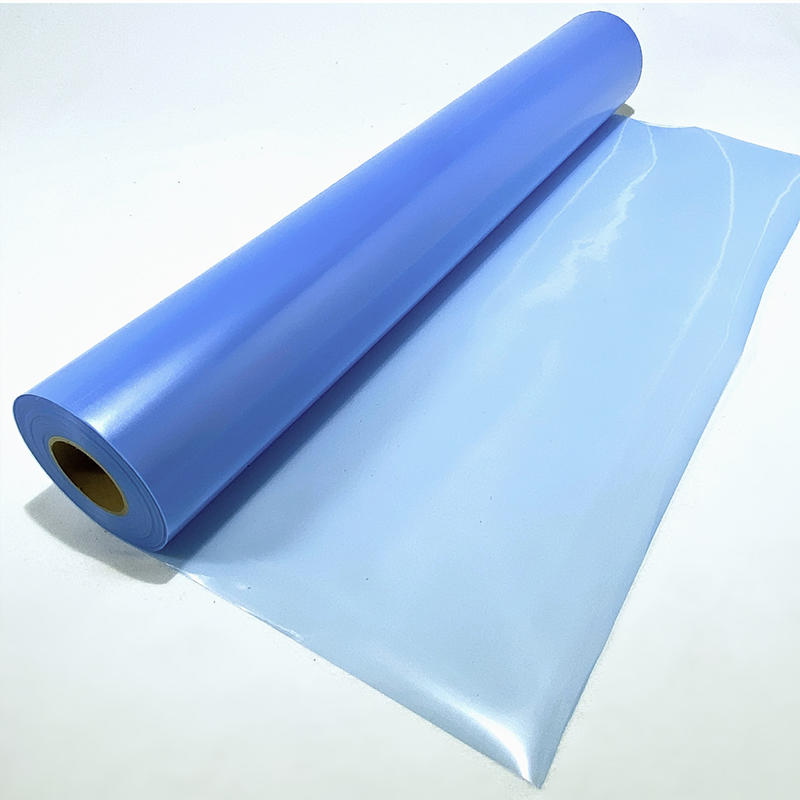

PE Protective Film, also known as Polyethylene Protective Film, is a type of temporary surface protection film used to safeguard various surfaces during manufacturing, transportation, storage, and installation processes. It is made from polyethylene, a thermoplastic polymer, and typically comes in the form of a thin, adhesive-backed film.

PE Protective Film is designed to provide a temporary barrier against scratches, abrasions, dust, dirt, moisture, and other potential damage that can occur during handling or other activities. It adheres to the surface it is applied to, creating a protective layer that can be easily peeled off and removed without leaving residue or damaging the underlying surface.

The film is commonly used to protect surfaces such as stainless steel, aluminum, glass, plastic, painted metal, laminate, and other smooth or lightly textured materials. It is widely employed in industries such as automotive, electronics, construction, furniture, appliances, and manufacturing, where it helps maintain the quality and appearance of the protected surfaces.

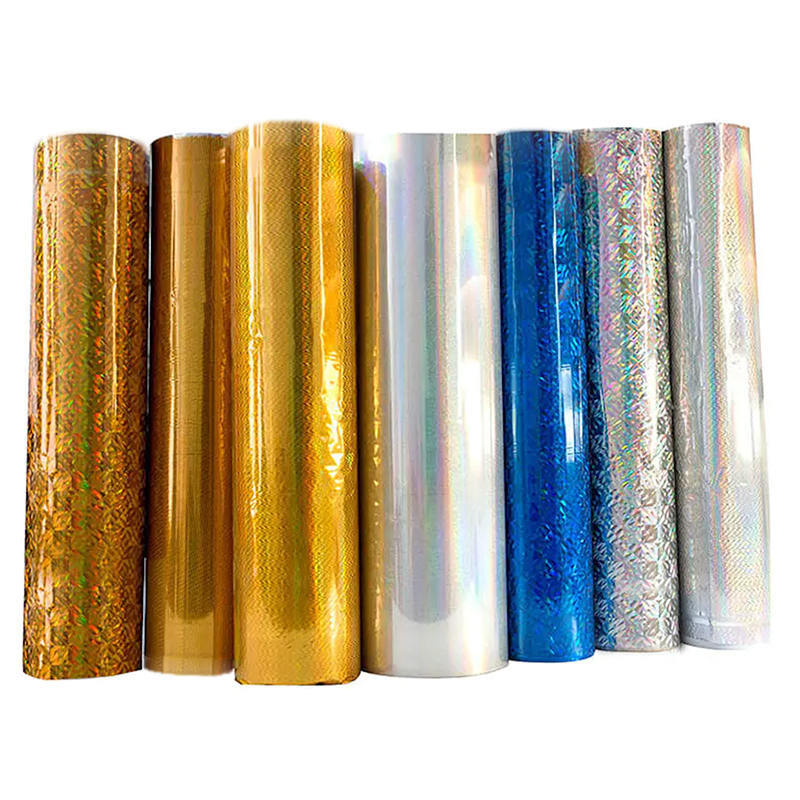

PE Protective Film comes in various thicknesses, adhesive strengths, and widths to suit different applications. It can be transparent or colored, depending on the desired level of visibility and identification. Some films also have additional features like UV resistance or anti-static properties, making them suitable for specific requirements.

Overall, PE Protective Film provides a cost-effective and efficient solution for temporary surface protection, minimizing the risk of damage and ensuring the surfaces remain in optimal condition until they are ready for use or further processing.Besides,PE Protective Films can be classified based on several criteria, including their application, adhesive type, thickness, and surface characteristics. Here are some common classifications:

Application-based Classification:

Surface Protection Film: Used to protect various surfaces, including metal, glass, plastic, and painted surfaces, from scratches, abrasions, and dirt during manufacturing, transportation, or installation processes.

Carpet Protection Film: Designed specifically to protect carpets and rugs from dirt, spills, and damage during construction, renovation, or high-traffic events.

Automotive Protective Film: Used to safeguard automotive surfaces, such as vehicle exteriors, hoods, bumpers, and door sills, from scratches, stone chips, and other damage.

Electronics Protective Film: Used to protect delicate electronic displays, touchscreens, and other sensitive components from scratches, dust, and fingerprints during manufacturing or transportation.

Adhesive-based Classification:

Acrylic Adhesive: PE films with acrylic adhesive offer good initial tack and adhesion to various surfaces. They are suitable for both indoor and outdoor applications.

Rubber Adhesive: PE films with rubber-based adhesive provide excellent conformability and are ideal for protecting delicate or sensitive surfaces.

Silicone Adhesive: PE films with silicone adhesive are commonly used for electronic applications, as they offer low-tack adhesion and can be easily removed without leaving residue.

Thickness-based Classification:

Thin PE Protective Film: Typically ranging from 20 to 70 microns, these films are suitable for protecting surfaces with low to medium risk of damage.

Medium PE Protective Film: Ranging from 70 to 100 microns, these films offer increased durability and are often used for surfaces that require moderate protection.

Thick PE Protective Film: Ranging from 100 to 200+ microns, these films provide heavy-duty protection for surfaces with high-risk exposure to potential damage.

Surface Characteristics:

Transparent PE Protective Film: Offers clarity and allows visual inspection of the protected surface.

Colored PE Protective Film: Provides color coding or identification purposes, making it easier to differentiate between different protected surfaces.

UV-resistant PE Protective Film: Protects surfaces from UV radiation, preventing color fading or damage caused by sunlight exposure.

Anti-static PE Protective Film: Designed to minimize static electricity and dust attraction, making it suitable for sensitive electronic components.

English

English

WeChat

WeChat WhatsApp

WhatsApp