Optical and printing plastic films can be classified based on various factors such as their optical properties, printing capabilities, and specific applications. Here are some common classifications of optical and printing plastic films:

Transparency:

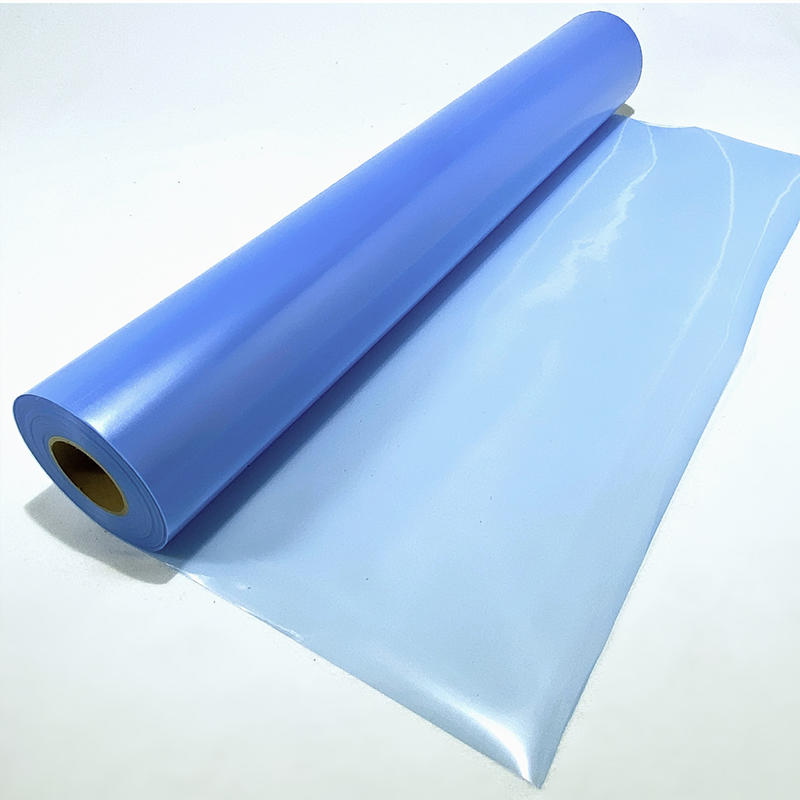

Clear Films: These films have high optical transparency, allowing light to pass through without significant distortion or scattering. They are commonly used for applications requiring visibility or clarity, such as packaging films or protective covers.

Translucent Films: Translucent films allow some light to pass through but diffuse it, resulting in reduced visibility. They are often used for applications that require diffused lighting effects, such as lightboxes or privacy films.

Optical Properties:

Anti-Glare Films: These films are designed to reduce glare and reflection from light sources, improving visibility and readability. They are commonly used in displays, signage, or electronic devices.

Anti-Static Films: These films are treated to minimize static electricity buildup, which can attract dust or cause interference in electronic components. They find applications in packaging or electronics manufacturing.

UV-Blocking Films: These films are engineered to block ultraviolet (UV) radiation, protecting sensitive products or materials from UV-induced damage. They are commonly used in window films, packaging, or artwork protection.

Printing Capabilities:

Printable Films: These films are specially coated to enhance printability, allowing for high-quality printing using various techniques such as flexography, gravure, or digital printing. They are commonly used for packaging, labels, or promotional materials.

Laminating Films: These films are used in lamination processes to provide a protective layer, improve durability, or enhance the visual appearance of printed materials. They can be glossy, matte, or textured, depending on the desired effect.

Specific Applications:

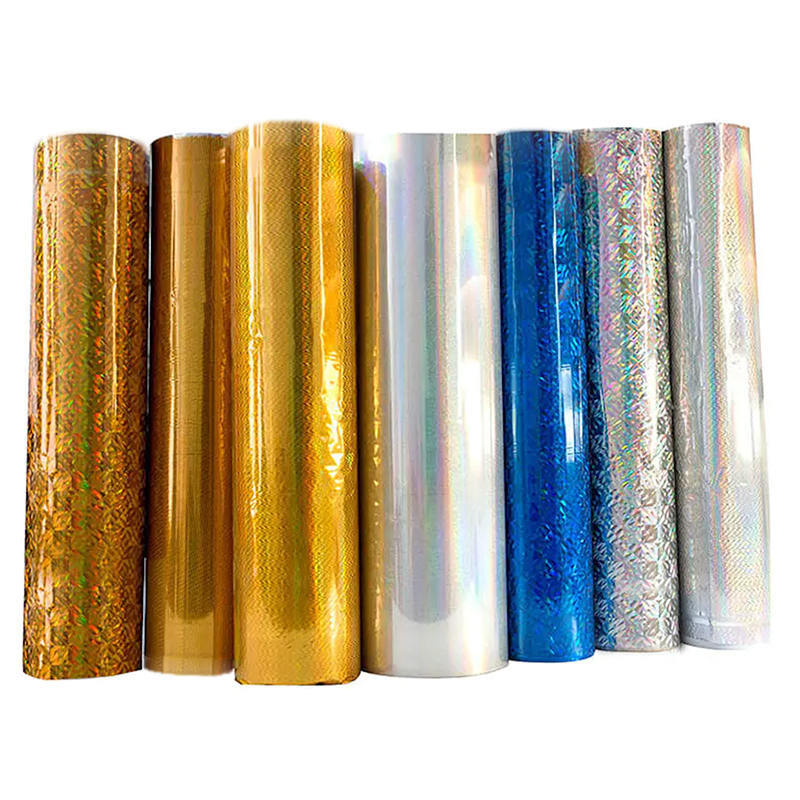

Security Films: These films incorporate features like holograms, tamper-evident properties, or authentication elements to provide security against counterfeiting or unauthorized access. They are often used in identity cards, banknotes, or high-security documents.

Optical Display Films: These films are engineered to enhance the visual performance of displays by improving contrast, brightness, or viewing angles. They are commonly used in LCD or OLED screens.

Haining Yahui Plastic Industry Co., Ltd. was established in 2003. Is a China PET Base Film Manufacturers and PET Base Film Suppliers With high-precision coating line, automatic cutting/winding machine, laminating machine, we focus on the R&D and production of optical and printing films. Products include: PE, PET, CPP, OPP, and PVC based films, which are widely used on packaging, PVC profiles, wall panels and flooring. Our quality, service, and price are the core competitiveness, we provide global customers with the highest quality products and solutions. We are sincerely looking forward to cooperating with you in the future.

Haining Yahui Plastic Industry Co., Ltd. was established in 2003. Is a China PET Base Film Manufacturers and PET Base Film Suppliers With high-precision coating line, automatic cutting/winding machine, laminating machine, we focus on the R&D and production of optical and printing films. Products include: PE, PET, CPP, OPP, and PVC based films, which are widely used on packaging, PVC profiles, wall panels and flooring. Our quality, service, and price are the core competitiveness, we provide global customers with the highest quality products and solutions. We are sincerely looking forward to cooperating with you in the future.

Haining Yahui Plastic Industry Co., Ltd. was established in 2003. Is a China PET Base Film Manufacturers and PET Base Film Suppliers With high-precision coating line, automatic cutting/winding machine, laminating machine, we focus on the R&D and production of optical and printing films. Products include: PE, PET, CPP, OPP, and PVC based films, which are widely used on packaging, PVC profiles, wall panels and flooring. Our quality, service, and price are the core competitiveness, we provide global customers with the highest quality products and solutions. We are sincerely looking forward to cooperating with you in the future.

Haining Yahui Plastic Industry Co., Ltd. was established in 2003. Is a China PET Base Film Manufacturers and PET Base Film Suppliers With high-precision coating line, automatic cutting/winding machine, laminating machine, we focus on the R&D and production of optical and printing films. Products include: PE, PET, CPP, OPP, and PVC based films, which are widely used on packaging, PVC profiles, wall panels and flooring. Our quality, service, and price are the core competitiveness, we provide global customers with the highest quality products and solutions. We are sincerely looking forward to cooperating with you in the future.Main features:Matte or gloss finish PET Films or Polyester based films are fabricated for high speed lamination feature that have robust adhesion and abrasion resistance. Also, it renders excellent resistance to scratch, tear and scuff.

Thickness:12-500μm.

Width:100-3200mm.

Length:According to your requirement.

English

English

WeChat

WeChat WhatsApp

WhatsApp