The advantages of PET (Polyethylene Terephthalate) base film, which is a type of plastic film, include:

Excellent Mechanical Properties: PET base film has high tensile strength, which makes it strong and durable. It can withstand tension and stretching without tearing or breaking easily. This property makes it suitable for various applications where strength and durability are essential.

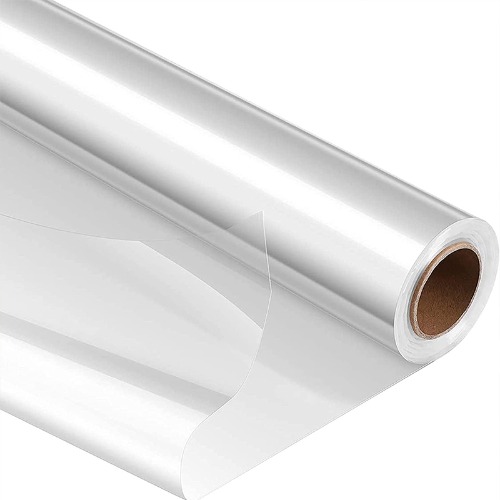

Optical Clarity: PET base film offers excellent transparency and clarity. It has a high light transmission rate, allowing for clear visibility of the contents or images printed on it. This makes it ideal for applications such as packaging, labels, and display materials where visual appeal is important.

Chemical Resistance: PET base film exhibits good resistance to chemicals, including acids, alkalis, and solvents. It does not readily react or degrade when exposed to common chemicals, making it suitable for packaging applications that involve contact with different substances.

Dimensional Stability: PET base film has excellent dimensional stability, meaning it retains its shape and size over time and under varying temperature and humidity conditions. This property is crucial for applications where accurate dimensions and consistent performance are required.

Barrier Properties: PET base film provides good barrier properties against moisture, oxygen, and other gases. It helps protect the packaged products from external factors that can deteriorate their quality or shelf life. PET film with enhanced barrier properties can be used for applications such as food packaging, electronics, and medical products.

Heat Resistance: PET base film exhibits good heat resistance and can withstand high temperatures without significant deformation or melting. This property makes it suitable for applications that involve heat sealing, thermal lamination, or exposure to elevated temperatures during processing or use.

Recyclability: PET base film is widely recyclable, contributing to sustainable and environmentally friendly practices. It can be recycled into new PET products or other polyester-based materials, reducing waste and conserving resources.

Classification of PET Base Film:

PET base film can be classified based on various characteristics and applications. Here are some common classifications:

Transparent PET Film: This type of PET film offers high clarity and transparency. It is commonly used in applications such as packaging, labels, graphic arts, and laminating films.

Metallized PET Film: Metallized PET film has a thin layer of metal deposited on one side, typically aluminum. It provides enhanced barrier properties against moisture, oxygen, and light. Metallized PET film is used in applications such as food packaging, decorative and reflective materials, and insulation.

Colored PET Film: PET film can be manufactured in various colors by incorporating colorants during the production process. Colored PET film is used for decorative purposes, displays, and packaging where aesthetic appeal or branding is important.

Heat Sealable PET Film: PET film with heat-sealable properties is designed to bond to itself or other materials when exposed to heat. It is used for applications such as flexible packaging, pouches, and sealing layers in laminates.

Matte PET Film: Matte PET film has a non-glossy or low-gloss surface finish. It is often used in applications where glare reduction, fingerprint resistance, or a tactile feel is desired, such as protective films, labels, and touch-sensitive displays.

English

English

WeChat

WeChat WhatsApp

WhatsApp