Installing PET base film can be a straightforward process if you follow these steps:

Clean the surface: Before installing the PET base film, ensure that the surface where it will be installed is clean and dry. Use a mild detergent and water to clean the surface, then wipe it dry with a clean cloth.Measure and cut: Measure the area where you will be installing the PET base film and cut the film to the appropriate size using a pair of scissors or a utility knife. It's important to leave a small margin around the edges of the surface to ensure proper adhesion.Apply adhesive: If the PET base film does not have a self-adhesive backing, you will need to apply adhesive to the surface before installing the film. Use a spray adhesive or a roll-on adhesive and apply a thin, even layer to the surface.Install the PET base film: Carefully place the PET base film onto the surface, starting from one edge and working your way across the surface. Use a squeegee or a flat-edged tool to press the film onto the surface, smoothing out any wrinkles or bubbles as you go.Trim the edges: Once the PET base film is in place, use a sharp blade to trim the excess film from the edges. Be careful not to cut into the surface underneath the film.Finishing touches: Once the installation is complete, use a clean cloth to wipe away any excess adhesive or debris. If necessary, use a heat gun or hair dryer on a low heat setting to help the film conform to curved surfaces or corners.

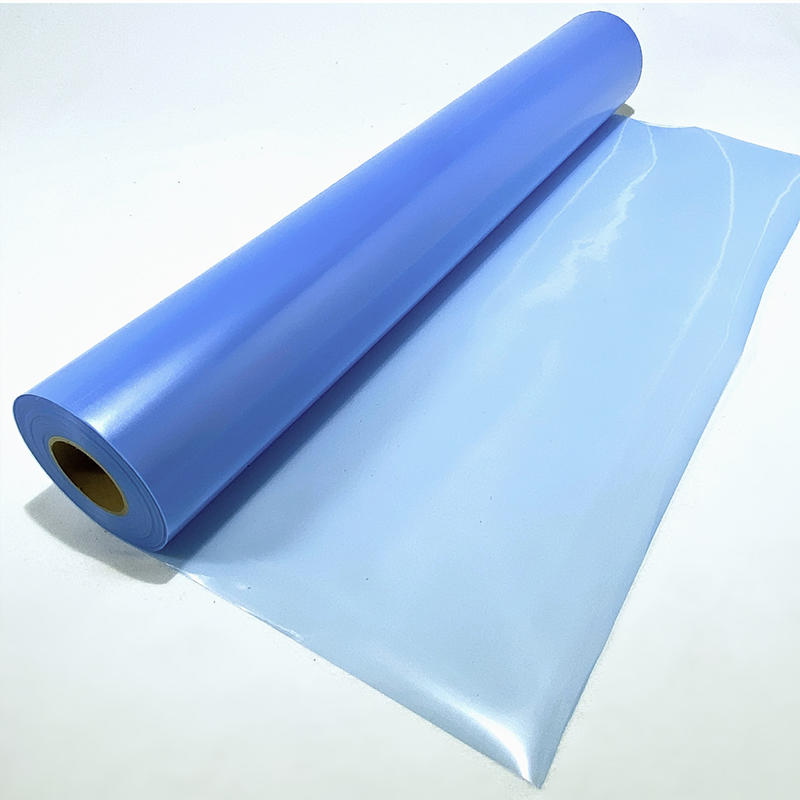

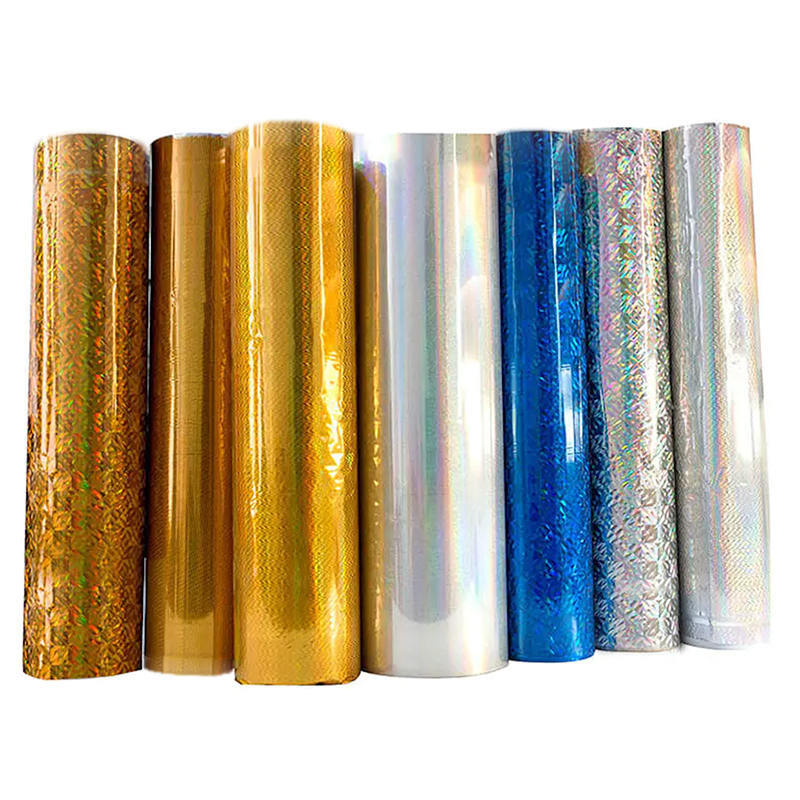

Following these steps can help you to install PET base film with ease and ensure a smooth, long-lasting finish.Besides,PET (Polyethylene terephthalate) base film is a type of plastic film that is commonly used for packaging and labeling applications due to its high strength, durability, and transparency. The structure of PET base film typically consists of the following layers:

Base Layer: This layer forms the backbone of the film and is made up of PET polymer. It provides the film with strength, rigidity, and dimensional stability.Adhesive Layer: In some cases, PET base film may have an adhesive layer on one side, which allows the film to adhere to surfaces such as paper or plastic.Coating Layer: PET base film can also have a coating layer applied to one or both sides of the film. The coating layer can be applied to improve the film's surface properties, such as scratch resistance, heat resistance, or UV stability.Printing Layer: PET base film can be printed on using various printing techniques, such as flexography or gravure printing. The printing layer allows for high-quality graphics and text to be printed onto the film.Barrier Layer: Some PET base films may have a barrier layer, which provides the film with additional protection against moisture, oxygen, and other environmental factors. The barrier layer can be made up of various materials such as EVOH, PVDC, or SiOx.

The specific structure of PET base film can vary depending on the intended application and the desired properties of the film. The different layers can be combined in various ways to create films with different properties such as flexibility, clarity, or gas barrier performance.

English

English

WeChat

WeChat WhatsApp

WhatsApp