Improving the ductility of metallized PET (Polyethylene Terephthalate) film involves modifying the film's properties to enhance its flexibility, stretchability, and resistance to cracking or breaking. Increasing the ductility of metallized PET film can make it more suitable for applications that require bending, shaping, or forming without compromising its metal coating or overall integrity. Here are some strategies to improve the ductility of metallized PET film:

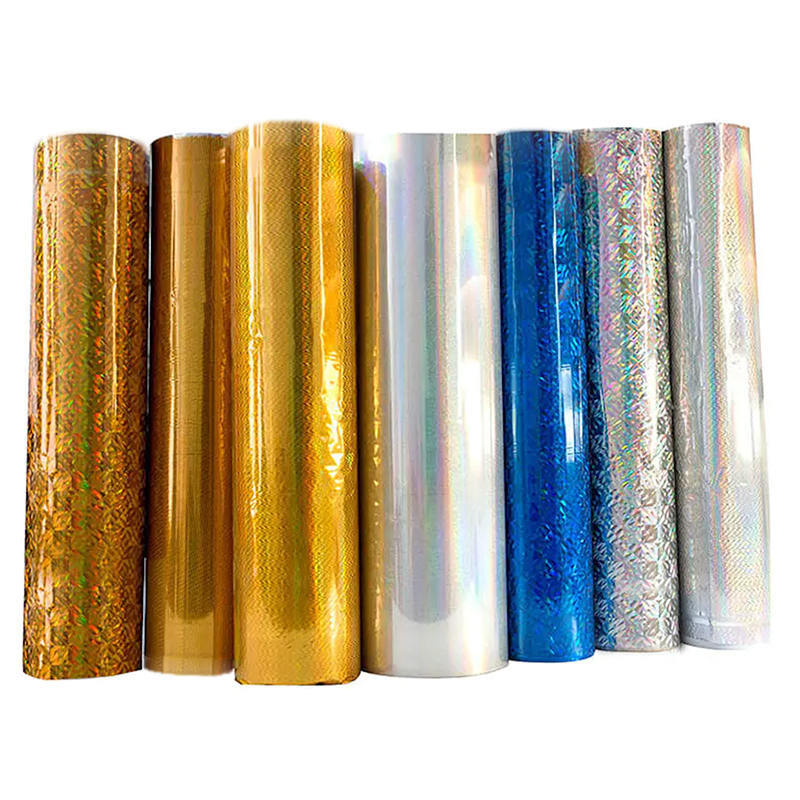

1. Optimize Metallization Parameters:

- Adjust the metallization process parameters, such as deposition rate and temperature, to minimize the impact on the film's inherent flexibility and ductility.

- Carefully control the metal coating thickness to avoid excessive stiffness.

2. Use Thinner Metal Coatings:

- Choose a thinner metal coating to retain more of the film's original flexibility.

- Thinner coatings can maintain a balance between metal protection and film ductility.

3. Add Flexible Coatings or Layers:

- Apply a protective layer or coating over the metal-coated surface to provide a barrier between the metal and the external environment.

- Select coatings with inherent flexibility to prevent cracks or delamination during bending or stretching.

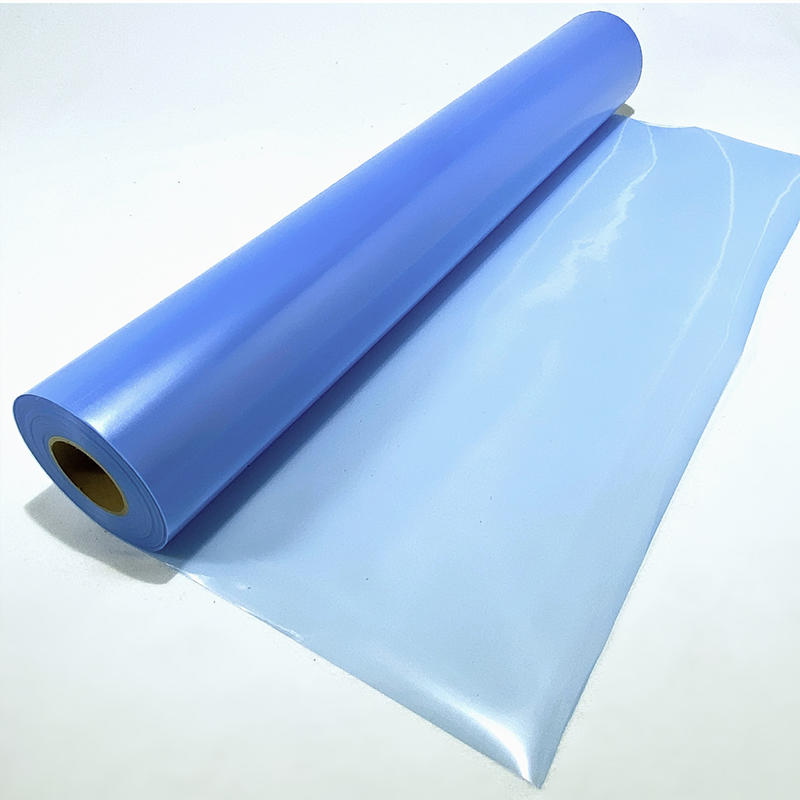

4. Select Suitable Substrates:

- Choose a PET substrate with optimized properties for enhanced flexibility and ductility.

- Ensure the base PET film is designed to withstand mechanical stress and elongation.

5. Surface Treatment:

- Apply surface treatment techniques such as corona treatment or plasma treatment to enhance the film's surface energy and adhesion properties, promoting better bonding between layers and reducing the risk of delamination.

6. Use Flexible Adhesives:

- Employ flexible and stretchable adhesives when laminating or bonding the metallized PET film to other materials.

- Adhesives with good flexibility can help maintain the film's ductility even in bonded areas.

7. Post-Metallization Processes:

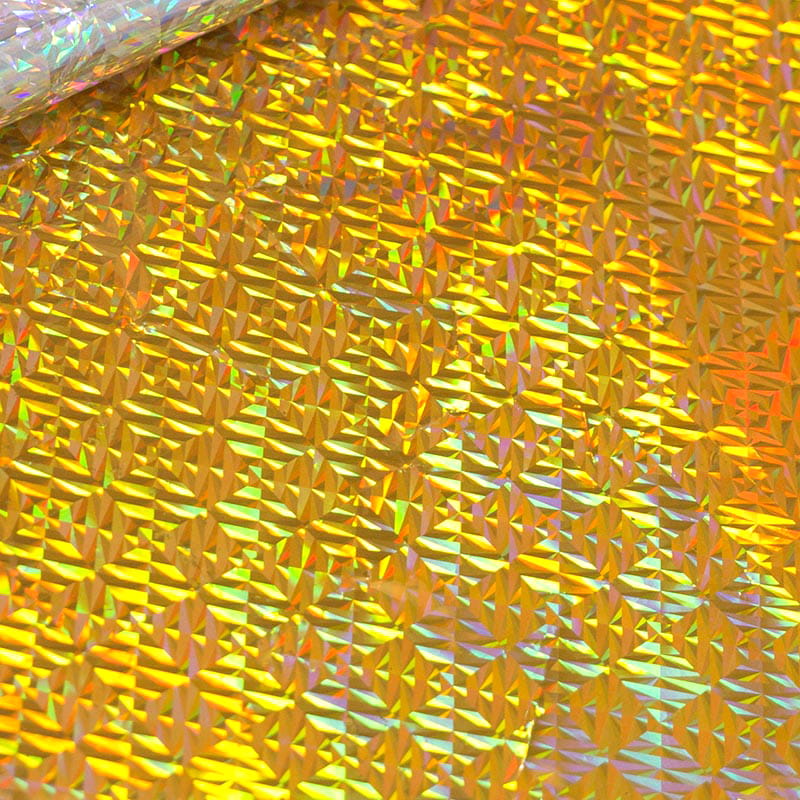

- Apply a post-metallization process, such as embossing or texturing, to introduce controlled deformation in the film, improving its ability to stretch and bend without breaking.

8. Film Thickness and Composition:

- Opt for thinner PET film substrates that inherently offer better flexibility and ductility.

- Balance the trade-off between film thickness and mechanical properties, considering the application's requirements.

9. Material Research and Development:

- Collaborate with material scientists and engineers to develop specialized PET formulations or composite materials that offer improved ductility while retaining other desired properties.

Improving the ductility of metallized PET film requires a combination of careful process optimization, material selection, and the application of appropriate techniques to maintain or enhance the film's flexibility and resistance to deformation.

English

English

WeChat

WeChat WhatsApp

WhatsApp