Choosing PVC edge banding involves considering various factors to ensure it meets the specific requirements of your project. PVC edge banding is a type of decorative material used to cover and protect the exposed edges of furniture and other surfaces. Here are the key factors to consider when selecting PVC edge banding:

Thickness: PVC edge banding comes in various thicknesses, typically ranging from 0.4mm to 3mm. Choose the appropriate thickness based on the thickness of the panel or board you are applying it to. The edge banding should be thick enough to cover the edge securely and provide protection.

Width: Consider the width of the edge banding in relation to the width of the panel. The edge banding should be wide enough to cover the edge fully without leaving any gaps or overhangs.

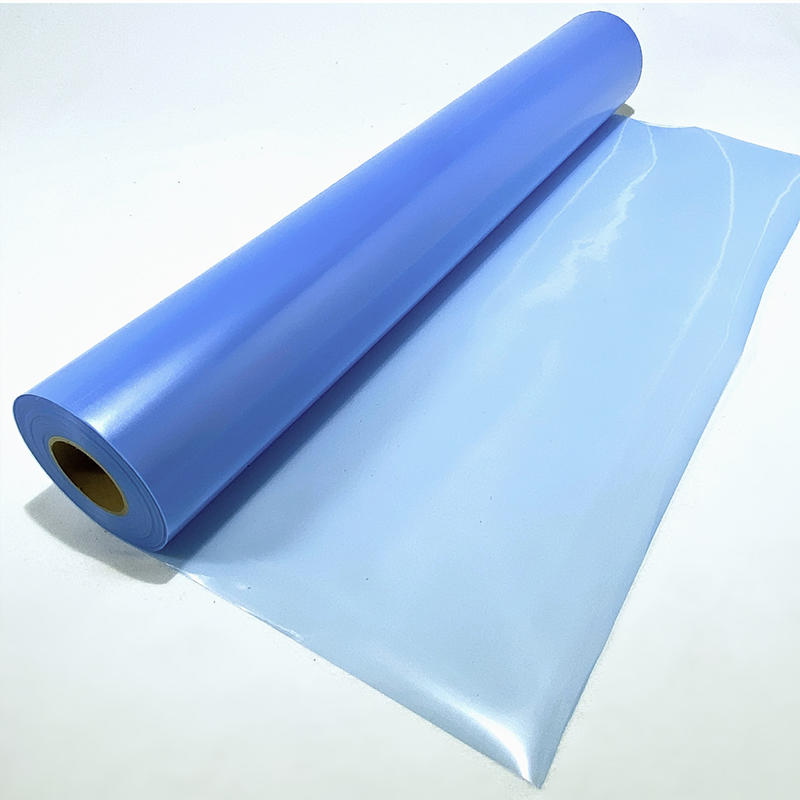

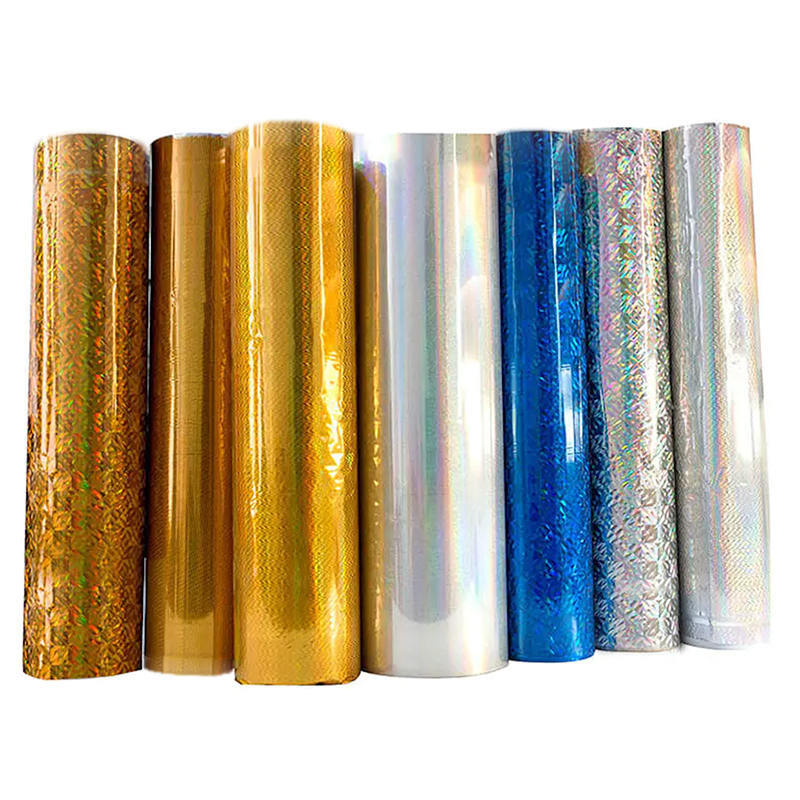

Color and Design: PVC edge banding comes in a wide range of colors and designs to match or complement the surface it is applied to. Choose a color and design that complements the overall aesthetic of your project.

Texture: PVC edge banding can have different textures, such as matte, glossy, or embossed. Select a texture that aligns with the desired finish of your furniture or surface.

Adhesive Quality: Ensure that the adhesive used on the edge banding is of high quality and provides strong bonding to the substrate. It should be heat-activated or pressure-sensitive adhesive, depending on the application method.

Durability and Wear Resistance: Look for edge banding that is durable and resistant to wear, scratches, and impact to ensure long-lasting performance.

Flexibility: PVC edge banding should be flexible enough to conform to curved or irregular edges without cracking or breaking.

Environmental Considerations: Consider eco-friendly options if sustainability is a concern. Some manufacturers offer PVC edge banding made from recycled materials or using more environmentally friendly production processes.

Quality and Brand: Choose edge banding from reputable brands known for producing high-quality products. Quality edge banding ensures better adhesion, color consistency, and overall performance.

Application Method: Consider the application method of the edge banding. It can be applied using hot air edge banding machines, pressure rollers, or other suitable equipment.

Price and Quantity: Compare prices and quantities available to find a cost-effective solution that meets your project's needs.

Compatibility: Ensure that the edge banding is compatible with the specific material you are using (e.g., MDF, particleboard, plywood).

English

English

WeChat

WeChat WhatsApp

WhatsApp